Resin 3D printing

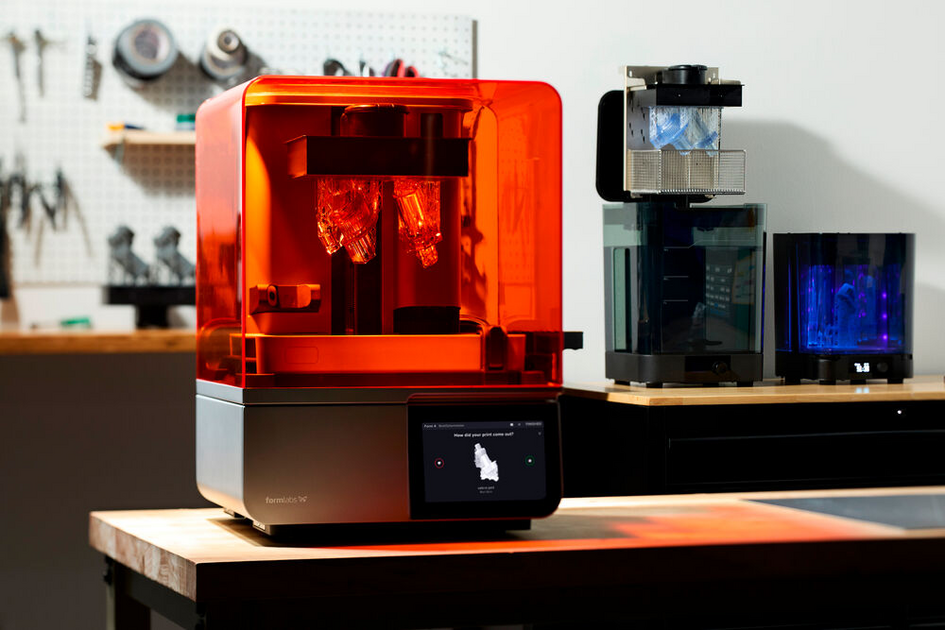

Formlabs introduces Form 4 and Form 4B, boosting productivity in professional 3D printing

Source:

Formlabs

Related Vendors

With the recent expansion of its portfolio, Formlabs is reinforcing its position at the forefront of the 3D printing industry. Its latest innovations include the Form 4 and Form 4B printers designed for increased speed and reliability.

(Source: Business Wire)

Formlabs announced the launch of the Form 4 and Form 4B, incorporating the company’s innovative Low Force Display (LFD) print engine. These new models are engineered to significantly enhance productivity in professional resin 3D printing, offering print speeds up to five times faster than previous models. This increase in speed enables professionals to innovate more freely in design and accelerate the time to market for new products.

Max Lobovsky, CEO and co-founder of Formlabs, noted the extensive experience backing the new models, with over 130,000 printers deployed and more than 300 million parts produced to date. “Its reliability and new level of speed will transform how our customers develop new products”, Lobovsky stated.

The Form 4 features several key enhancements, including new masked stereolithography (mSLA) technology that completes most prints in under two hours — significantly faster than the Form 3+. The advanced LFD print engine boasts a high-power backlight, proprietary release texture, Light Processing Unit 4 (LPU 4), and a dual-layer resin tank. It ensures an industry-leading print success rate with validated settings, precision heating, force sensing, and debris detection. Print quality is also elevated, with 50-micron pixels, highly collimated light, advanced pixel smoothing, and light touch supports, all contributing to superb detail and finish.

Ease of use is another major focus. The printer supports automatic resin handling, instant material changes, and a quick-release build platform, simplifying the overall operation. Additionally, the Form 4 offers enhanced affordability, achieving a 40 percent lower cost per part through durable resin tanks, reduced resin prices, increased print volume, and higher throughput.

The company has also expanded its materials library to include six new resins, such as redesigned General Purpose Resins and specialty options like Fast Model Resin and Precision Model Resin, particularly catering to the dental industry. The Form 4 is compatible with over 17 materials from the existing library, with 15 additional biocompatible materials suitable for the Form 4B model.

(ID:50008330)